I like hairnets. I also like making them - it is a nice thing to do with the hands, without much thinking. My nets, however, are a far cry from some of those medieval ones that are still extant.

A lot of people know the nets found in London - with mesh sizes between 3 and 9 mm, depending on the net. But they are really simple.

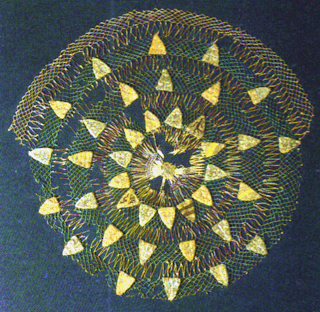

Now take this one, as one of the not-too-elaborate nets. We don't know where it comes from, unfortunately, since it was bought via art trade, but it has been dated to the last quarter of the 13th century. Nowadays, it is in the Art Museum in Düsseldorf.

(picture clickable for larger version)

Diameter is 33 cm, and it has been worked in green and white silk. I had to tune up the colours on the scan, and now it should be easy to see where the green and where the white silk was used. I would have expected the small, embroidered shields-with-arms on a white background. Shame on my modern mind - green it is. The arms are embroidered in spun silk and gilded silver wrapped around a textile core. The ground for embroidering was coarsely woven linen. Some of the arms have been identified: there's six times Sayn and eight times Geldern, pointing to the Middle or Lower Rhine region. The net might have served for a wedding or proposal ceremony. In addition to the 38 arms, there's a little six-petaled rosette in the middle of the net.

The netting should not be too hard to do, using two different-size gauges for the long white and the small green meshes. My rough estimate is 3-4 mm for the small green mesh and about 1.5 cm length for the long white mesh - which is "not very small" for green and "exceptionally large" for white. It would be very interesting to see it close up, and in good detail, to see whether it was worked in spirals or in rounds, and whether the colour thread not in use was cut off or just led down for the next colour change. Any odd joints caused by this could be covered up easily with the embroidery bits sewn on later.

Source for the net picture and information: FANSA, MAMOUN (Hrsg.): der sassen speyghel. Sachsenspiegel - Recht - Alltag. Beiträge und Katalog zur Ausstellung "Aus dem Leben gegriffen - Ein Rechtsbuch spiegelt seine Zeit". Bd. Beiheft 10, Band 2, Archäologische Mitteilungen aus Nordwestdeutschland. Oldenburg 1995.

A lot of people know the nets found in London - with mesh sizes between 3 and 9 mm, depending on the net. But they are really simple.

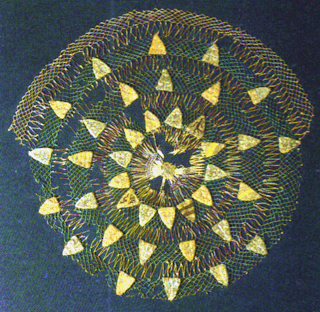

Now take this one, as one of the not-too-elaborate nets. We don't know where it comes from, unfortunately, since it was bought via art trade, but it has been dated to the last quarter of the 13th century. Nowadays, it is in the Art Museum in Düsseldorf.

Diameter is 33 cm, and it has been worked in green and white silk. I had to tune up the colours on the scan, and now it should be easy to see where the green and where the white silk was used. I would have expected the small, embroidered shields-with-arms on a white background. Shame on my modern mind - green it is. The arms are embroidered in spun silk and gilded silver wrapped around a textile core. The ground for embroidering was coarsely woven linen. Some of the arms have been identified: there's six times Sayn and eight times Geldern, pointing to the Middle or Lower Rhine region. The net might have served for a wedding or proposal ceremony. In addition to the 38 arms, there's a little six-petaled rosette in the middle of the net.

The netting should not be too hard to do, using two different-size gauges for the long white and the small green meshes. My rough estimate is 3-4 mm for the small green mesh and about 1.5 cm length for the long white mesh - which is "not very small" for green and "exceptionally large" for white. It would be very interesting to see it close up, and in good detail, to see whether it was worked in spirals or in rounds, and whether the colour thread not in use was cut off or just led down for the next colour change. Any odd joints caused by this could be covered up easily with the embroidery bits sewn on later.

Source for the net picture and information: FANSA, MAMOUN (Hrsg.): der sassen speyghel. Sachsenspiegel - Recht - Alltag. Beiträge und Katalog zur Ausstellung "Aus dem Leben gegriffen - Ein Rechtsbuch spiegelt seine Zeit". Bd. Beiheft 10, Band 2, Archäologische Mitteilungen aus Nordwestdeutschland. Oldenburg 1995.