Both Beatrix and Harma have posted comments about the Egtved cording and the efficiency of the method, or how to make it faster. (Thank you, both of you, for your input! It's much appreciated.)

Cording by hand is always a relatively slow procedure. It can be made a bit quicker with several methods; one way is like Beatrix suggested, using both hands to insert twist.

In some cases, it's even possible to use the hands and leg to roll the two elements into one direction on the leg, then hold them together and ply them by rolling in the opposite direction. Whether that is possible or not depends on the material, the dexterity of the maker, and - last but not at all least - on the required or desired amount of twist to be inserted.

I find that the more twist is needed, the slower the whole process will be, and simultaneously it becomes harder to speed it up with these small changes to procedure. With more twist inserted, the elements get more "lively" and will untwist much easier than with less twist. That is the reason why my fingers are so close to the fell in the video, and why I only insert a little bit of twist before each cross. I have tried to work further away from the fell, inserting more twist at a time, but the probability of losing much of that when doing the crossing (or plying) then is quite high, which makes that method less efficient than the one shown in the video. At least for me - it may be different for someone else. These making things are, after all, very individual.

Regarding the use of both hands to insert said twist: I actually do this, though it is very hard to see in the video. There's only a rather small motion of the left hand fingers before the cross, but it is there. What does take time is the crossing over, and I can't see myself going much faster on that than I am doing already. The elements have to be transferred carefully, or they will lose the necessary twist for the density of the cording. There's probably a bit of speed-up possibility left with more practise, but I don't see much improvement lingering close by. The elements are quite thin which means a lot of crossings, and as stated, those are what takes time. It takes me about 6 minutes to make one cord with this method.

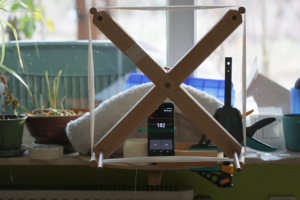

That all said, Harma's suggestion was the use of a modern tool to speed up things... which is what I actually do for production. (My cord twisting tool is different from the Ashford tool mentioned, though, and more suitable for the specific requirements of the skirt cords.) The estimate of about 1/10th of the time is, unfortunately, not true - that would be wonderful, and extremely fast. That might be the case for a very long cord with a relatively soft twist, but for mine, the speed difference is much less - though still considerable, which is exactly why I use the tool.

Cording by hand is always a relatively slow procedure. It can be made a bit quicker with several methods; one way is like Beatrix suggested, using both hands to insert twist.

In some cases, it's even possible to use the hands and leg to roll the two elements into one direction on the leg, then hold them together and ply them by rolling in the opposite direction. Whether that is possible or not depends on the material, the dexterity of the maker, and - last but not at all least - on the required or desired amount of twist to be inserted.

I find that the more twist is needed, the slower the whole process will be, and simultaneously it becomes harder to speed it up with these small changes to procedure. With more twist inserted, the elements get more "lively" and will untwist much easier than with less twist. That is the reason why my fingers are so close to the fell in the video, and why I only insert a little bit of twist before each cross. I have tried to work further away from the fell, inserting more twist at a time, but the probability of losing much of that when doing the crossing (or plying) then is quite high, which makes that method less efficient than the one shown in the video. At least for me - it may be different for someone else. These making things are, after all, very individual.

Regarding the use of both hands to insert said twist: I actually do this, though it is very hard to see in the video. There's only a rather small motion of the left hand fingers before the cross, but it is there. What does take time is the crossing over, and I can't see myself going much faster on that than I am doing already. The elements have to be transferred carefully, or they will lose the necessary twist for the density of the cording. There's probably a bit of speed-up possibility left with more practise, but I don't see much improvement lingering close by. The elements are quite thin which means a lot of crossings, and as stated, those are what takes time. It takes me about 6 minutes to make one cord with this method.

That all said, Harma's suggestion was the use of a modern tool to speed up things... which is what I actually do for production. (My cord twisting tool is different from the Ashford tool mentioned, though, and more suitable for the specific requirements of the skirt cords.) The estimate of about 1/10th of the time is, unfortunately, not true - that would be wonderful, and extremely fast. That might be the case for a very long cord with a relatively soft twist, but for mine, the speed difference is much less - though still considerable, which is exactly why I use the tool.

Maple wood on top, cherry wood on the bottom.

Maple wood on top, cherry wood on the bottom.