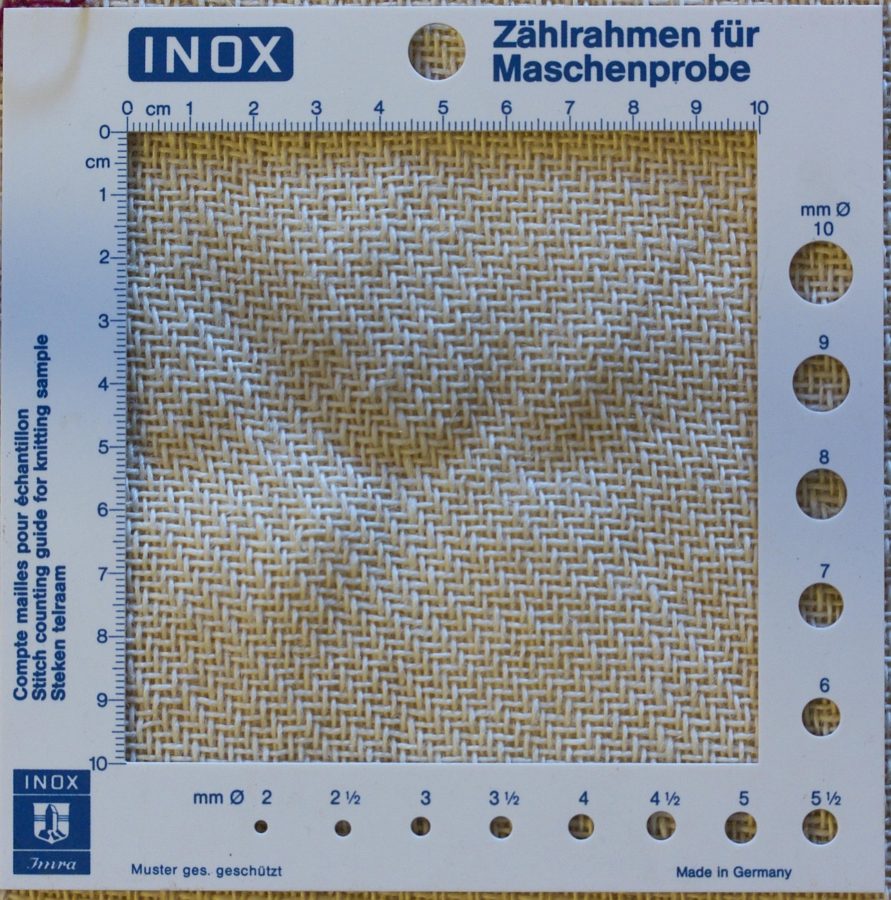

The last of the fabrics for the project has arrived - a 2/2 twill woven from the same yarns as the previous plainweave fabric. It's now hanging out to dry after being fulled just like the others... and it's beautiful. Really, really beautiful.

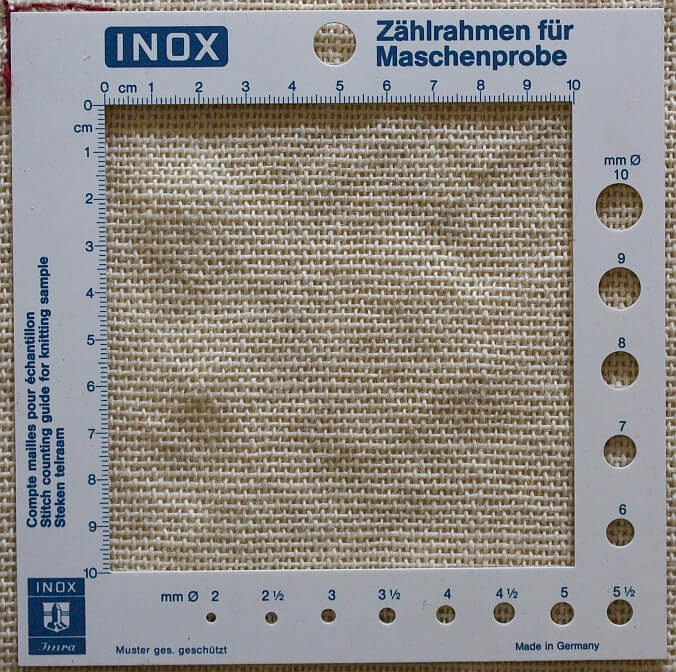

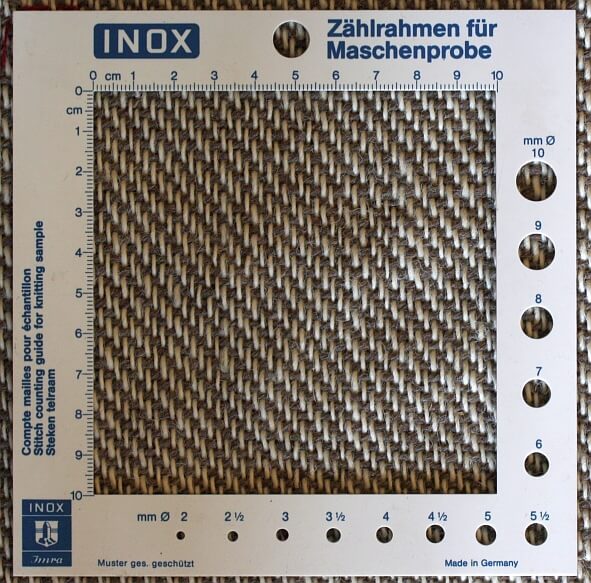

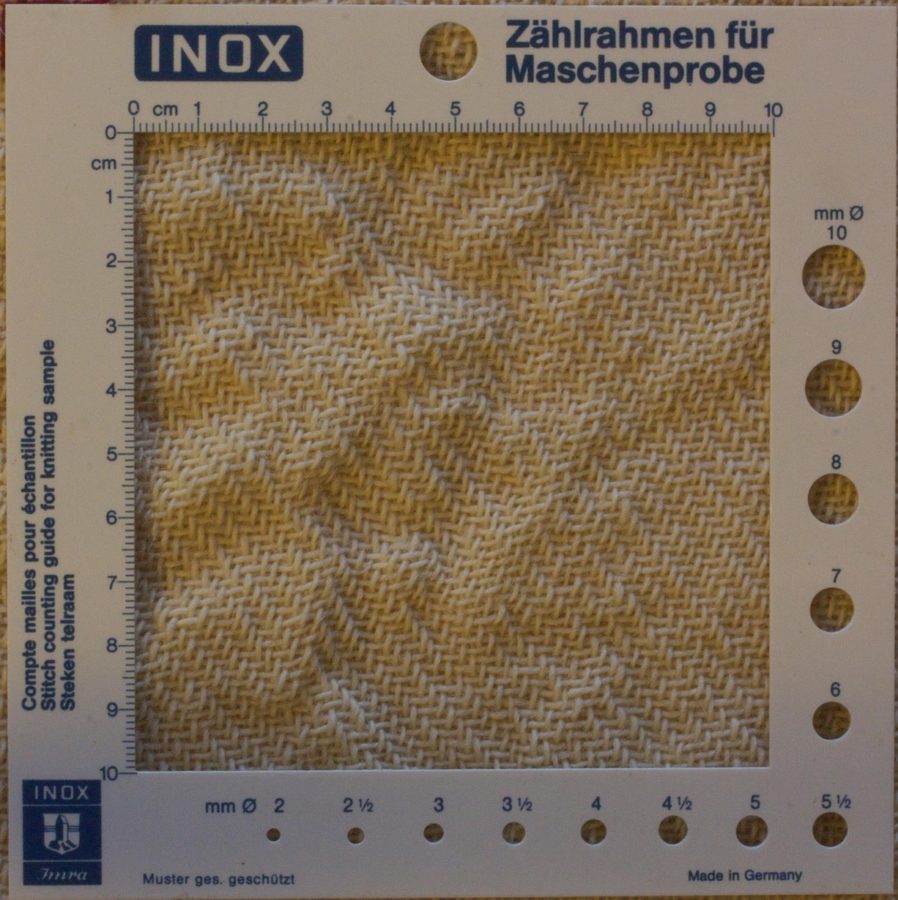

Here's the cloth in its raw state:

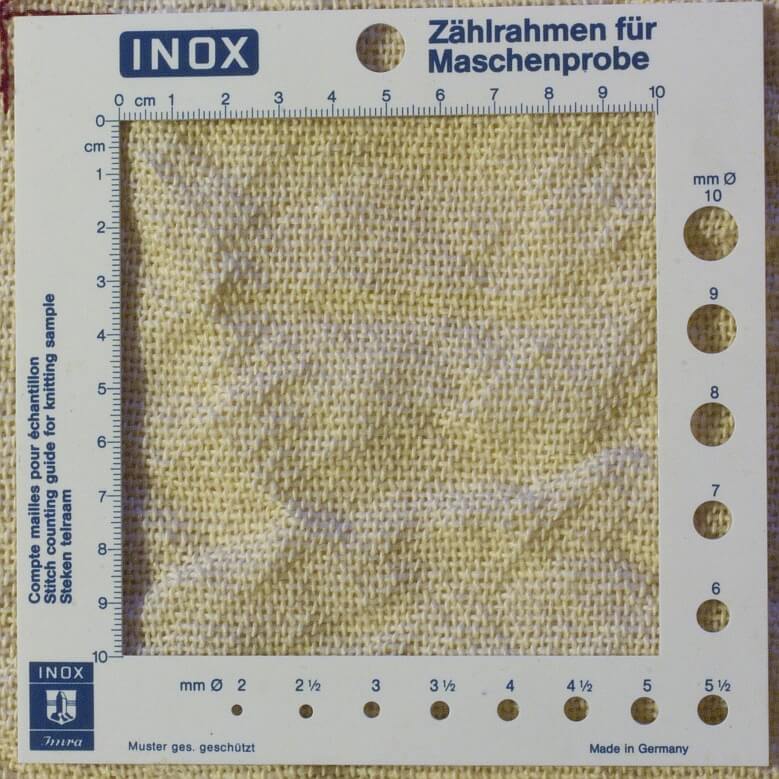

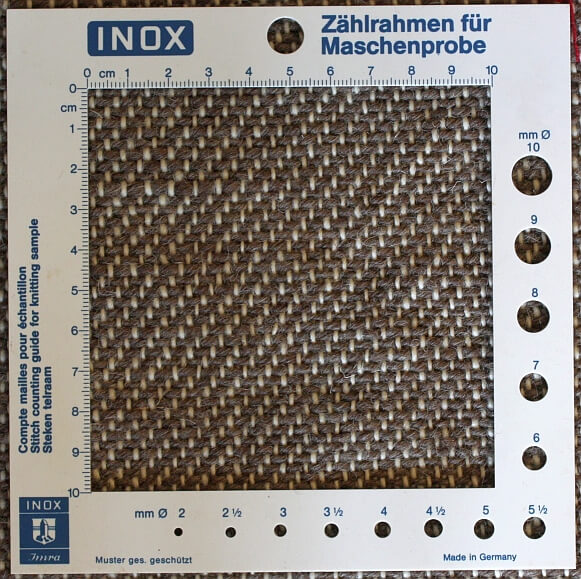

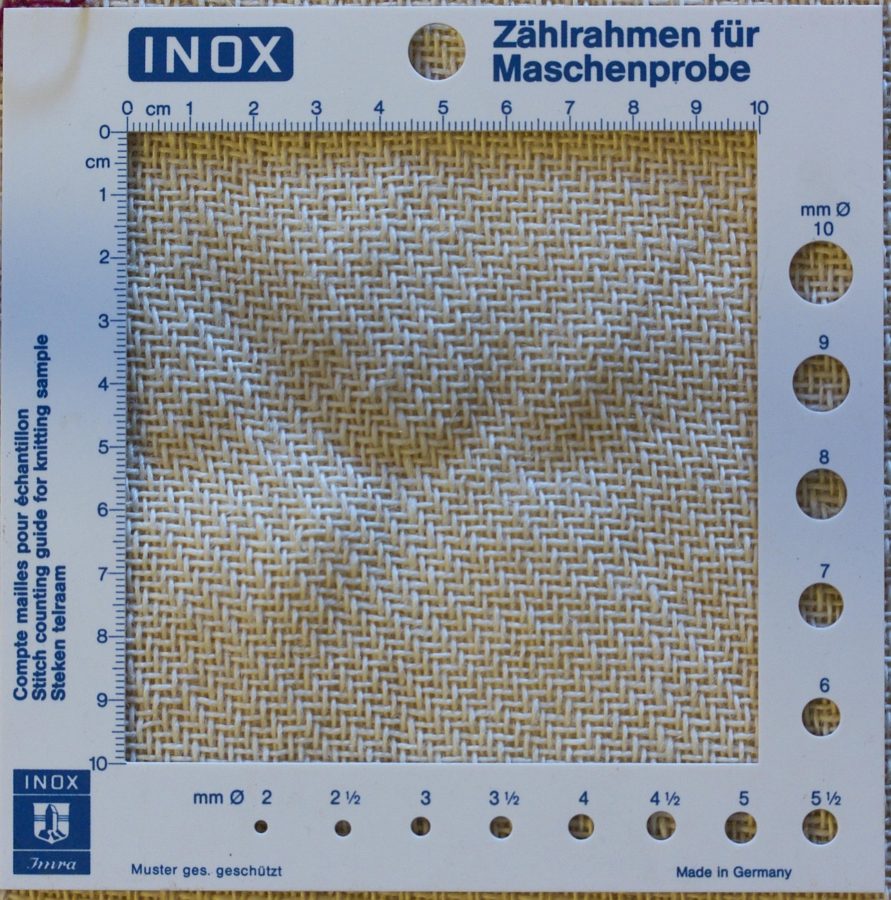

And this is what it looked like after washing:

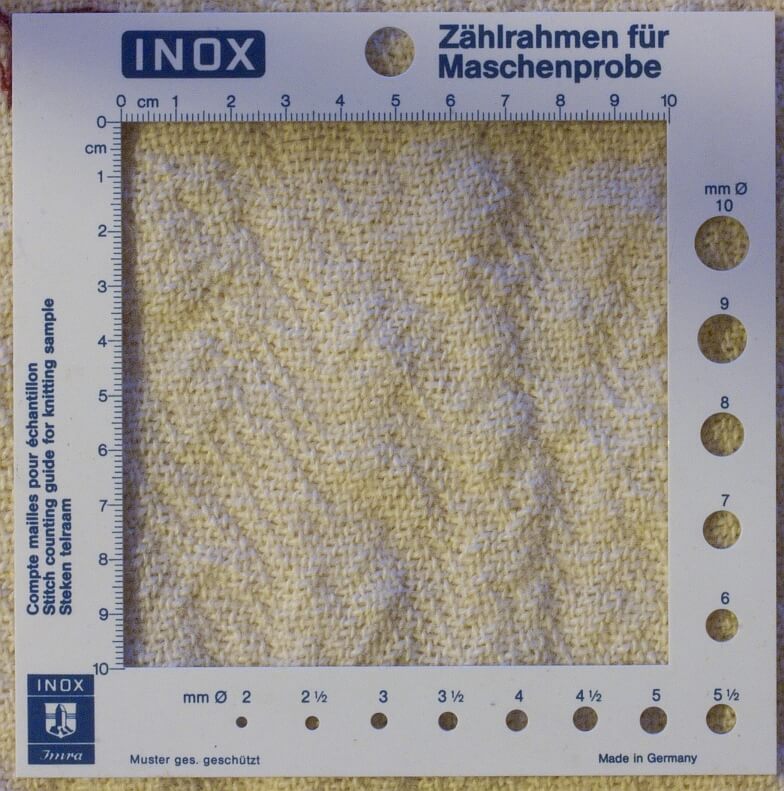

The last picture of the after-fulling state will have to wait for tomorrow when it's dry again - but I can already tell you that the fabric shows no tracking, hasn't shrunk a lot, and is really nice.

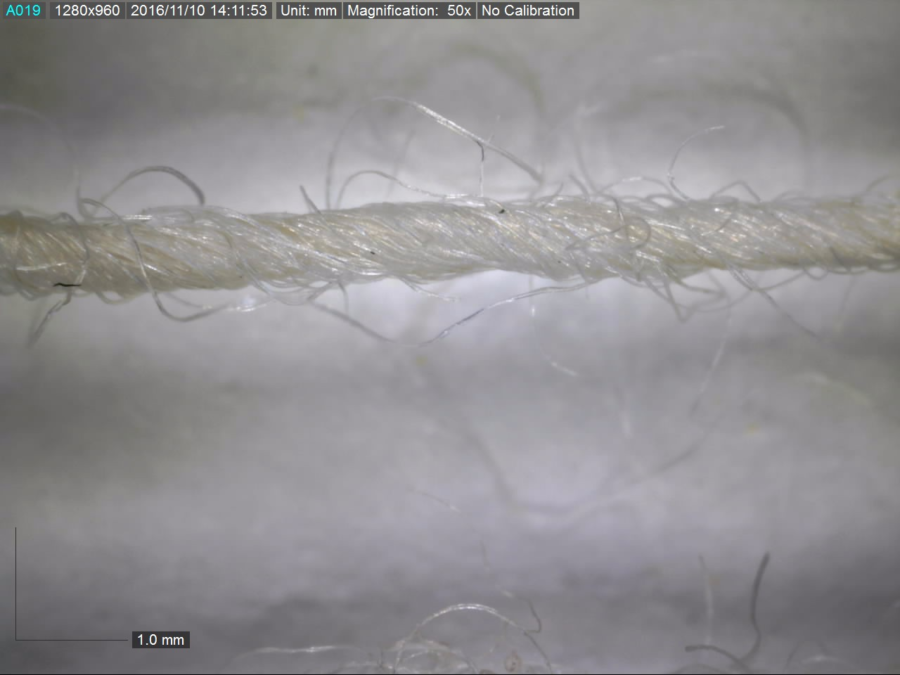

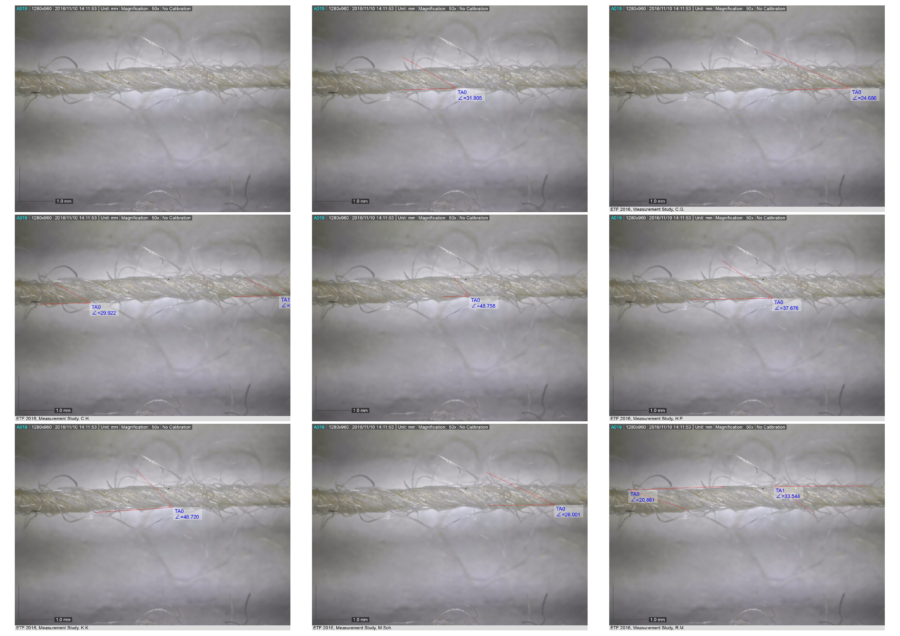

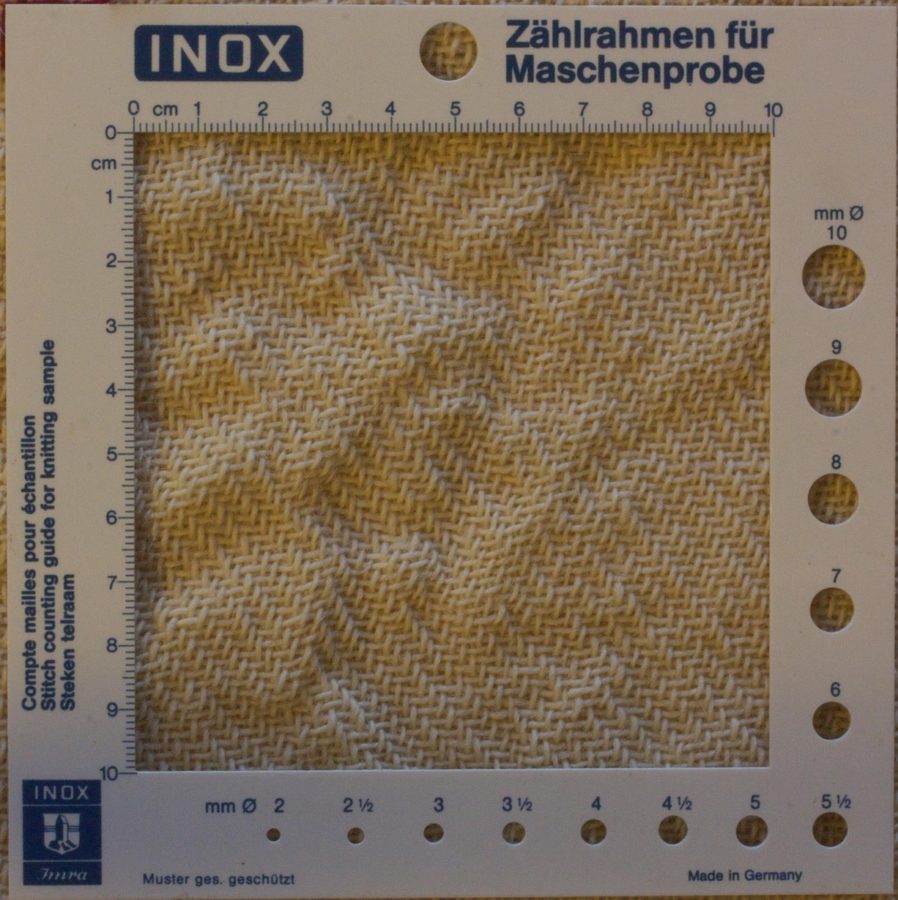

Here's a closeup of the threads after washing:

And tomorrow, it will go off to new adventures - cloth metamorphosis part two!

Here's the cloth in its raw state:

And this is what it looked like after washing:

The last picture of the after-fulling state will have to wait for tomorrow when it's dry again - but I can already tell you that the fabric shows no tracking, hasn't shrunk a lot, and is really nice.

Here's a closeup of the threads after washing:

And tomorrow, it will go off to new adventures - cloth metamorphosis part two!