If you're a spinner, you will probably know what "setting the twist" means. For those of you who don't know what that is about, let me explain.

When you spin yarn, you twist fibres together, pressing their surfaces onto each other. Friction between these surfaces gives the thread its stability - hence a thread with more twist is usually a stronger thread. Yarn thickness, fibre length and fibre surface all influence how much twist is needed for a certain amount of yarn strength.

Twisting these fibres together means inserting energy into a system - that is what you do when you flick the spindle or treadle the wheel. This energy (and may the proper natural scientists please forgive any odd wording) is stored in the fibres. Now when you let go of the piece of twisted yarn, the fibres want to return to their relaxed state (and there's probably something that could be said about the laws of thermodynamics here, or something equally smart). So... they will untwist as far as possible.

"Setting the twist" means counteracting this, by getting the individual fibres settled into their new shape. This can be done by time (just letting the yarn sit will eventually deform the fibres) or be sped up by the application of heat and moisture. So dunking the skein in hot water, then hanging it up (possibly a little bit weighted, so the yarns remain stretched out) will help nicely. For those of us with less time, or less patience, or wanting to take before and after pictures, a steam cleaner will also deliver heat and moisture, conveniently at the push of a button.

So. I always thought that setting the twist would do just that - set the twist in the yarn, sort of freeze it in its current state. However, there seems to be something more happening here:

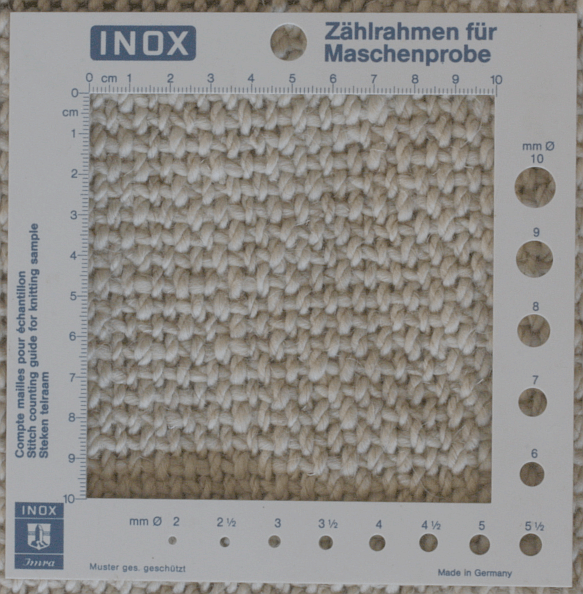

[caption id="attachment_2867" align="alignnone" width="640"]

Yarn before and after steam treatment - you can see how the knot of the marking yarn moves. There is definitely a difference in the yarn after steaming!

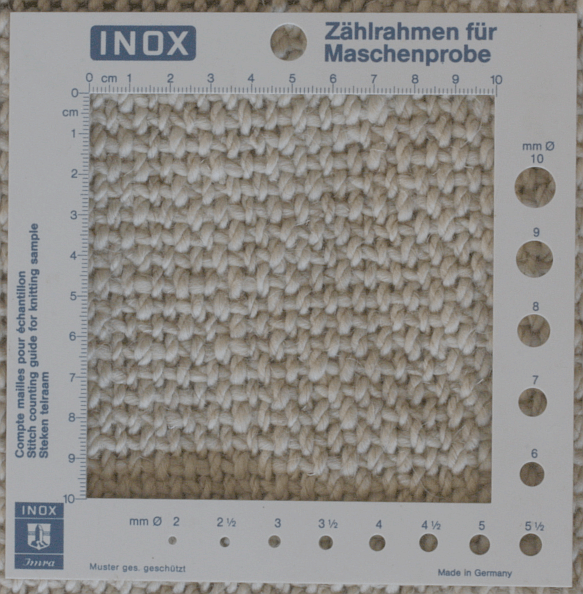

Here's a closeup of the part with the marked yarn:

I haven't measured yet if the twist angle changes noticeably, but the yarns definitely move and shift and something happens to them when they get treated. Some of that movement could be explained by the steam shifting the threads, but not all of it - I tried not to get too close with the nozzle and be gentle enough to avoid shifting the yarn with the steam stream, and still things happened.

Well. Who would have guessed that...