There I am, making slow but steady progress! The belt has been finished, and now I'm back on the corded section of the Egtved skirt:

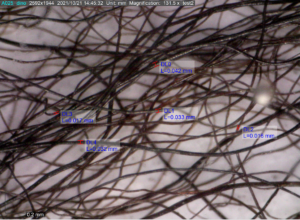

Yes, I'm working on the floor - I put the warp there on a hunch, and I'm very glad now that I took that decision. While it may not seem as comfy for working as seated at a table, it gives me the possibility to use my foot (or, to be precise, my left big toe) to assist with things. The wooden piece you see in the middle of the photo is used to measure off the cord lengths, and I hold both this measuring thing and, on top of it, the last loop pulled through the previous shed, in place with my toe. That way I don't have to do too many loops at once, which results in loops crossing each other, and me having to sort them out again, and/or in distortion of the weave or changes in loop length. This way, I do each shed's loops as a separate batch, pulling them out, then letting them ply up. Then they are put out of the way. After a while of weaving, I've taken a break from that and started twisting the cords; to have something else to do for a change, and to prevent huge tangles from having too many cords to deal with at once (though I suspect that would not happen, really).

The cords are much longer than the ones on the belt end, and quite a bit thinner, so they do feel and behave rather differently. I'm also not yet happy about the rings, there will have to be some more tests to find the right amount of fibre to wrap around to arrive at the proper size and thickness for the rings. Unfortunately there's no picture showing them clearly from all sides, so part of this will remain guesswork.

To the right of my measuring and weaving tool, you can see the to-scale-printout of the original skirt, which serves as my guideline and to check if I'm about right. This is immensely helpful to have, it's so difficult to work just from descriptions and written measurements!

Yes, I'm working on the floor - I put the warp there on a hunch, and I'm very glad now that I took that decision. While it may not seem as comfy for working as seated at a table, it gives me the possibility to use my foot (or, to be precise, my left big toe) to assist with things. The wooden piece you see in the middle of the photo is used to measure off the cord lengths, and I hold both this measuring thing and, on top of it, the last loop pulled through the previous shed, in place with my toe. That way I don't have to do too many loops at once, which results in loops crossing each other, and me having to sort them out again, and/or in distortion of the weave or changes in loop length. This way, I do each shed's loops as a separate batch, pulling them out, then letting them ply up. Then they are put out of the way. After a while of weaving, I've taken a break from that and started twisting the cords; to have something else to do for a change, and to prevent huge tangles from having too many cords to deal with at once (though I suspect that would not happen, really).

The cords are much longer than the ones on the belt end, and quite a bit thinner, so they do feel and behave rather differently. I'm also not yet happy about the rings, there will have to be some more tests to find the right amount of fibre to wrap around to arrive at the proper size and thickness for the rings. Unfortunately there's no picture showing them clearly from all sides, so part of this will remain guesswork.

To the right of my measuring and weaving tool, you can see the to-scale-printout of the original skirt, which serves as my guideline and to check if I'm about right. This is immensely helpful to have, it's so difficult to work just from descriptions and written measurements!

Getting there! There's a little bit of fibre sticking out of the wrap, but overall it looks good to my eyes.

Getting there! There's a little bit of fibre sticking out of the wrap, but overall it looks good to my eyes.