I'm back from the Forum and my recuperation afterwards - much needed, and much appreciated, and now it's tackling all the emails that have accumulated, and sending out all the orders that came in, and then... back to normal work plus the Forum homework.

And oh, there's homework. We ran a total of four experiments and one dyeing test during the week (yes, madness indeed). One was the continuation of Micky Schoelzke's exploration of fake purple that she started last year (you can read about that on the Forum homepage). Then I had the splendid idea of trying out mordanting with horsetail (equisetum arvense), which was an experiment on its own. Then there were the dyeing tests - a first trial at reconstructing some early modern recipes for dyeing knitted caps, with the three great providers of red: madder, cochenille, and kermes. Micky had an experiment with madder as well, a spin-off from the fake purple research, using madder root that had been pre-treated in different ways.

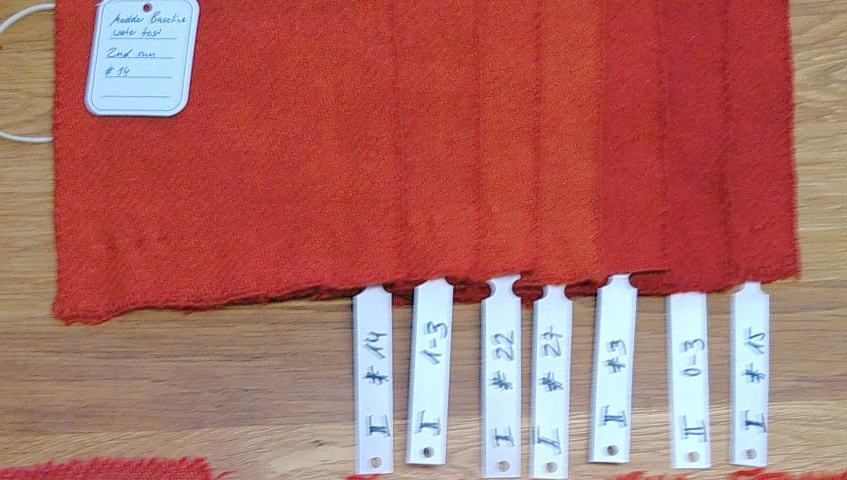

And then, of course, there was the Madder Baselines experiment. We had the staggering number of 35 different water samples for testing the dyeing outcome and the influence of the water on the dye result... so that was huge, and ate up all the time available, and then some. Especially since the experiment went not just as planned.

It was rather clear when we were getting ready that the amount of goods was very large for our small beakers - but there's the decision to make between having very small samples (where any fluctuations in amounts of madder, or the quality of the teaspoonful you are using compared to the quality of the second teaspoonful for the next sample will make more of a difference the smaller your samples are) or having larger samples and larger amounts of dyestuff but running the risk of uneven dyeing.

We decided to go for larger samples and the risk of spotting... which, in retrospective, was not a good decision, as spotting was very, very prominent. So we went for the afterbath - which was another mordanting run, and another dye run. That did not satisfy us with the results, so we decided to use the waters that we had more of to do a second run, with more liquid and thus less of a risk of uneven dyeing. Another batch of samples to make, another mordanting run, another dye run.

And then we had to test the different madders that we got - mordanting and dyeing in de-ionised water, to make things all even and comparable.

Long (very long!) story short: We did get to see some differences depending on the waters used, but they were not as pronounced as we would have expected them to be. There's also a difference between the different madders. Now the last factor that would need to be checked is... the Human Factor. Because the speed with which you heat your dyebath, the temperature, they also might make a difference.

Fortunately, most of the Forum participants volunteered in taking part of this experiment, and dyeing a sample at home. Which is why this happened today:

I harvested some more madder from the garden yesterday, and today it was dried enough (I sped the process up a bit) to be ground, and now it can finish dyeing... and then there'll be a test run of my instructions for the volunteers, and then these can be sent out.

And then we'll see. I am very, very curious if there will be differences visible - after all, it's the same madder, the same samples, the same mordant, the same instructions, and the same water (de-ionised water for the win!).

What's your guess? Will we have differences? Or will it all look the same?