Both the coffee cup weaving and the UFO weaving took place while there was a pen-and-paper roleplaying session going on in the same room, which for me sort of qualifies as "mildly distractive environment". So for my expectations, the system is robust enough; it does happen occasionally that I forget to re-order a few tablets, but I usually catch this even before turning them, and if I don't, it becomes really obvious right afterwards, and is easy to fix. (Turn the offenders back, sort, re-turn them.)

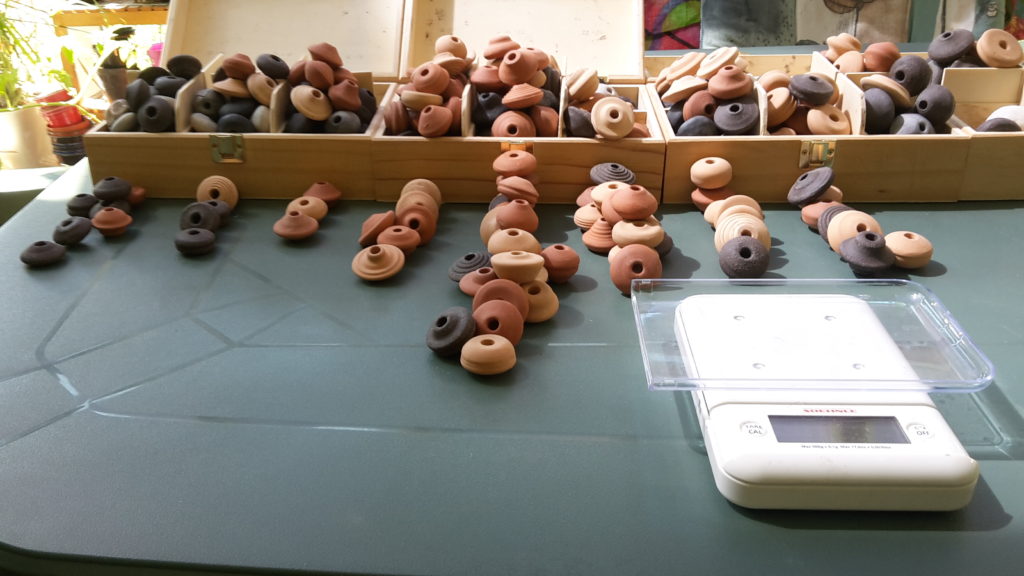

Something that happens even more occasionally, but that is much, much more of a nuisance: Forgetting a weft thread. This has really obnoxious results. First of all, it only becomes rather obvious a good while after the vile deed has happened, and I'm usually not willing to unweave two picks to fix the issue. Unfixed, the forgetting of a weft results in long floats across the width of the band, which can be very obvious if you are looking at the structure (or are a nitpicky person and are looking for mistakes). It actually happened twice when I was doing the UFO, see if you can find the spots:

Have you found them?

The second effect of forgetting a weft, which is at least as annoying, is that I use the side the shuttle hangs on as an indicator of what may or may not be done at that stage, pattern-wise. So having forgotten a weft, this changes, which can be confusing, even when using a marker on one side of the band to keep track of the "do-things-side" as opposed to the "maintenance-mode-side".

I complained about this to the Most Patient Husband Of Them All, and he quite correctly said that there must be a way to see that the weft thread is missing... so we spent a while discussing all the possible ways we could, collectively, think of.

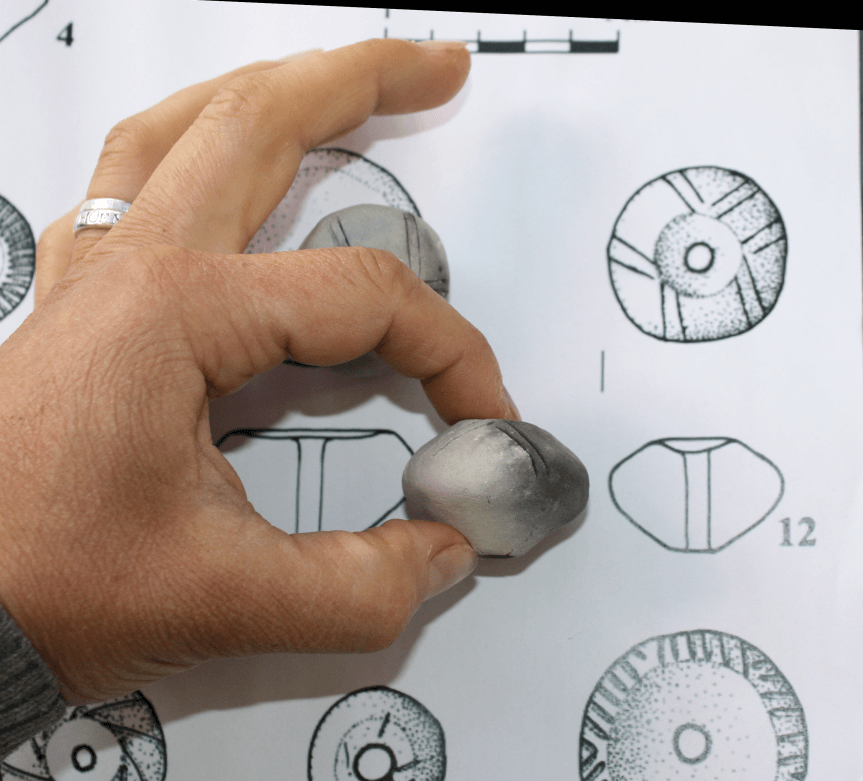

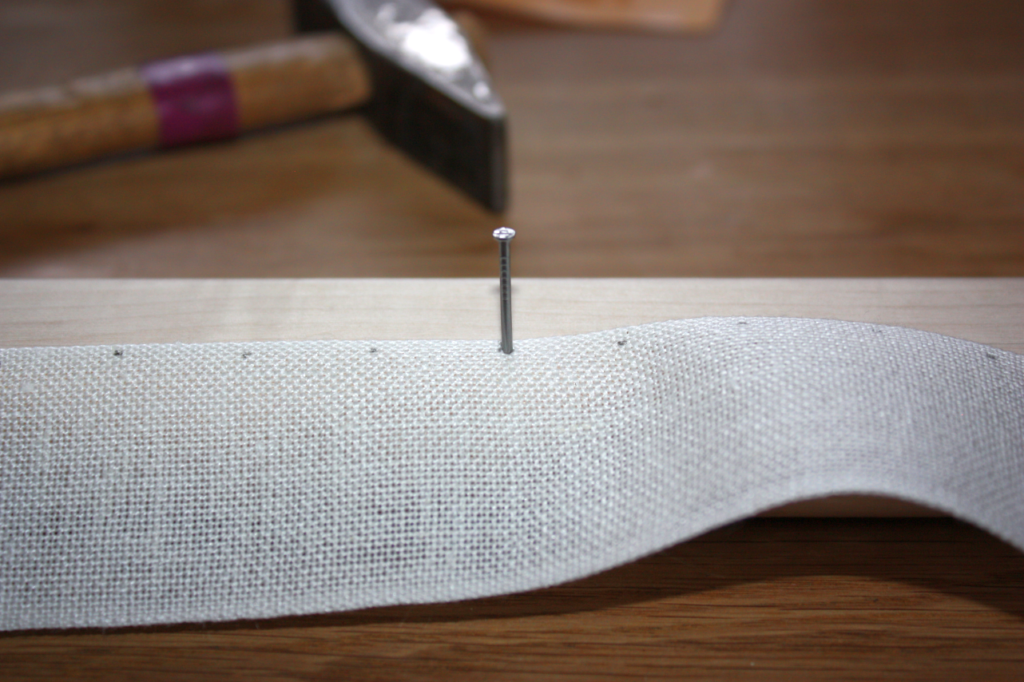

The end result was that since the missing weft causes a change in the band structure, it is possible to see it right after you turn the tablets and press in the shed. However, since every thread is only tied down by the weft every fourth pass, this means only every fourth tablet shows this structural difference - so it is visible, but it is very subtle.

Here is how it looks with the weft thread in:

And this is the same pick without the weft thread:

It's no wonder I never noticed before when I had missed putting in a weft (and none of my students did when this happened in a workshop). Now that I know what to look for, though, I'll keep an eye open for the telltale tiny gaps on the edge of the weaving knife when pressing in.

Are you occasionally forgetting the weft? Do you go back when that happens to you?